Auto-tuner

P

Problem We

Have Solved

Although conventional fuzzy logic controllers (FLCs) are powerful, they still suffer from a challenging problem: that of tuning the parameters. Like all expert systems, the FLC parameters (called the Knowledge-Base, or KB) is a complex structure consisting of a large number of parameters including rules and membership functions, as well as other values such as scaling factors, rule weights, and gains.

T

The Need for Automated

FLC tuning

In fuzzy logic control applications, FLC tuning involves selecting the values of the FLC parameters (Knowledge-Base or KB) that yield the optimal control response. Substantial trial-and-error is normally required to generate and tune the KB, and further optimization in the operating environment is needed to achieve optimum control quality through repeated experiments. Therefore, KB generation and tuning can only be performed by fuzzy logic experts, and require significant effort and time.

It can be seen that developing a system for the auto tuning of fuzzy controllers will save project time and effort and will widen fuzzy logic applications. Such a tool will help the expert, as well as the novice, to apply fuzzy logic technology to industrial systems without the effort of understanding the intricacies of KB acquisition and tuning.

A

Approximate

Model

The advantage that a FLC has over other controllers, such as the PID, is that it does not need an accurate model of the process. With the PID, the more accurate the model is, the better the tuned parameters are, while an approximate model is sufficient to obtain good FLC tuning. This makes a substantial difference since obtaining an accurate model can be a challenge.

Designers can use edeX to generate the process model.

Get Quote

O

Our

Solution

Xiera has developed the Auto-tuner, a powerful and unique system for intelligent and fuzzy controller tuning which automates the FLC knowledge-base optimization process. The Auto-tuner is capable of generating optimum values of the FLC parameters, which yield process behavior that satisfy the user’s specifications.

The Auto-tuner is a fuzzy expert system which employs fuzzy decision making, heuristics and machine learning technologies. It uses intelligent cost functions and constraints, which are described using powerful fuzzy logic formulation through which intelligent fuzzy decision making is utilized for task analysis for the solution of the fuzzy controller tuning problem.

The Auto-tuner opens new possibilities for the application of fuzzy logic control to industrial and embedded systems. It widens the application of this technology to new and untapped areas including the control of complex industrial systems.

Get Quote

B

Benefits of the

Auto-tuner

- Creating more designs and architectures of fuzzy controllers which are extremely powerful and possess very fast

response, but require more complex parameters to tune which is not possible manually. - Gives the fuzzy controller more degrees of freedom.

- The user can employ hierarchical fuzzy controllers for highly complex control systems.

- The user can tackle multivariable control systems without the daunting task of manually tuning the fuzzy logic parameters.

Using edeX to Tune the

Fuzzy Controller

A

Auto-tuning

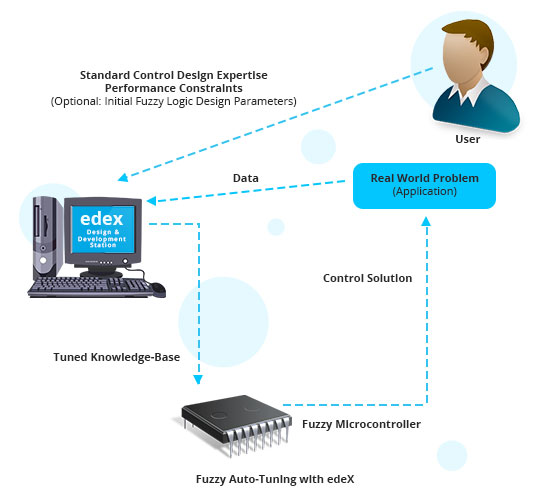

In the automatic tuning mode, the user tunes the fuzzy controller by working with the process model, employing the fuzzy design software to automatically optimize the FLC parameters. The tuned KB is then downloaded to the chip for online testing.

O

On-Line Manual Tuning

On-line manual tuning is performed directly on the process, iteratively editing the knowledge-base, and downloading it to the microcontroller, to validate the controller operation on the process.

O

Off-Line Manual Tuning

Off-line manual tuning is performed on the process model with a simulated control loop. The FLC parameters are iteratively changed and simulated to improve the controller response. The tuned KB is then downloaded to the target for online testing.

I

Interactive Tuning

Users can stop the automatic tuning at any time to make manual changes to the FLC configuration. Combining manual editing with automatic search allows for the greatest level of flexibility and control of the design process.